Additive manufacturing, often referred to as 3D printing, is revolutionising the way we design, prototype, and produce objects across various industries. This innovative technology enables the creation of complex three-dimensional structures by building them layer by layer, offering unprecedented flexibility and efficiency in manufacturing processes. As the technology continues to advance, it’s opening up new possibilities in fields ranging from aerospace and automotive to healthcare and consumer goods.

Fundamentals of additive manufacturing processes

At its core, additive manufacturing is a process that creates objects by depositing materials in layers based on digital 3D models. This approach stands in stark contrast to traditional subtractive manufacturing methods, where material is removed from a larger block to create the desired shape. The additive process allows for the creation of intricate geometries that would be difficult or impossible to achieve with conventional manufacturing techniques.

One of the key advantages of additive manufacturing is its ability to produce complex parts without the need for tooling or moulds. This significantly reduces lead times and costs associated with prototype development and small-scale production runs. Additionally, the layer-by-layer construction process enables the creation of internal structures and hollow sections that can enhance a product’s performance while reducing its weight.

The process typically begins with a 3D computer-aided design (CAD) model, which is then sliced into thin layers by specialised software. These layers serve as the blueprint for the additive manufacturing machine, guiding the deposition of material to build the object from the ground up. This digital-to-physical workflow allows for rapid iteration and customisation, making additive manufacturing an invaluable tool for industries that require frequent design changes or personalised products.

Materials science in 3D printing technologies

The evolution of additive manufacturing has been closely tied to advancements in materials science. As the technology has progressed, the range of materials available for 3D printing has expanded dramatically, enabling the production of parts with diverse properties and applications. From common plastics to high-performance metals and ceramics, the material palette for additive manufacturing continues to grow, driving innovation across industries.

Thermoplastics: ABS, PLA, and PETG properties

Thermoplastics are among the most widely used materials in additive manufacturing, particularly for desktop 3D printers and rapid prototyping applications. These materials offer a balance of ease of use, cost-effectiveness, and versatility. The most common thermoplastics in 3D printing include:

- Acrylonitrile Butadiene Styrene (ABS): Known for its durability and impact resistance

- Polylactic Acid (PLA): Biodegradable and easy to print, popular for prototyping

- Polyethylene Terephthalate Glycol (PETG): Combines strength with flexibility and chemical resistance

Each of these materials has unique properties that make them suitable for different applications. For example, ABS is often used in automotive parts and consumer electronics due to its toughness, while PLA is preferred for prototypes and educational models due to its ease of use and low environmental impact.

Metal powders: titanium, aluminium, and stainless steel

Metal additive manufacturing has seen significant growth in recent years, driven by the demand for high-performance parts in aerospace, automotive, and medical industries. The use of metal powders in processes like Selective Laser Melting (SLM) and Direct Metal Laser Sintering (DMLS) allows for the creation of complex metal parts with properties comparable to traditionally manufactured components.

Titanium alloys, such as Ti6Al4V, are prized in aerospace and medical applications for their high strength-to-weight ratio and biocompatibility. Aluminium alloys offer excellent thermal conductivity and low density, making them ideal for automotive and aerospace components. Stainless steel powders provide corrosion resistance and high strength, suitable for a wide range of industrial applications.

Photopolymers: resins for SLA and DLP printing

Photopolymer resins used in Stereolithography (SLA) and Digital Light Processing (DLP) printers offer exceptional surface finish and fine detail resolution. These liquid resins are cured by light, allowing for the production of smooth, accurate parts with intricate features. Photopolymers are particularly useful in industries requiring high-precision prototypes, such as jewellery design and dental applications.

Recent advancements in photopolymer chemistry have led to the development of resins with enhanced mechanical properties, including increased flexibility, heat resistance, and biocompatibility. This expansion of material properties has broadened the application range of SLA and DLP technologies beyond prototyping into functional end-use parts.

Composite materials: carbon fiber and kevlar infusions

The integration of composite materials in additive manufacturing has opened up new possibilities for creating parts with exceptional strength-to-weight ratios. Carbon fiber-reinforced plastics, for instance, combine the ease of printing thermoplastics with the strength and stiffness of carbon fibers. These materials are increasingly used in aerospace and high-performance automotive applications where weight reduction is critical.

Kevlar-infused filaments offer enhanced impact resistance and durability, making them suitable for protective gear and industrial components subject to high wear. The ability to precisely control the orientation and distribution of reinforcing fibers within a printed part allows for optimisation of mechanical properties in specific directions, tailoring the material’s performance to the application’s requirements.

Layer-by-layer fabrication techniques

The heart of additive manufacturing lies in its layer-by-layer approach to building objects. This methodology allows for the creation of complex geometries and internal structures that would be challenging or impossible to achieve with traditional manufacturing methods. Various techniques have been developed to accommodate different materials and achieve specific part properties.

Fused deposition modeling (FDM) methodology

Fused Deposition Modeling, also known as Fused Filament Fabrication (FFF), is one of the most common and accessible additive manufacturing techniques. In FDM, a thermoplastic filament is heated and extruded through a nozzle, depositing material layer by layer to build the object. This process is widely used in desktop 3D printers and is popular for rapid prototyping and small-scale production.

FDM offers several advantages, including relatively low equipment costs, a wide range of available materials, and the ability to produce parts with good mechanical properties. However, it typically has lower resolution compared to some other additive manufacturing techniques and may require post-processing to achieve a smooth surface finish.

Stereolithography (SLA) and digital light processing (DLP)

Stereolithography (SLA) and Digital Light Processing (DLP) are resin-based technologies that use light to cure liquid photopolymers into solid objects. SLA uses a laser to trace out and cure each layer, while DLP projects entire layers at once using a digital light projector. Both techniques are known for their high resolution and smooth surface finish, making them ideal for applications requiring fine details and aesthetically pleasing results.

SLA and DLP are commonly used in industries such as jewellery design, dental applications, and high-detail prototyping. The main difference between the two lies in the light source and curing method, with DLP often offering faster build times for certain geometries.

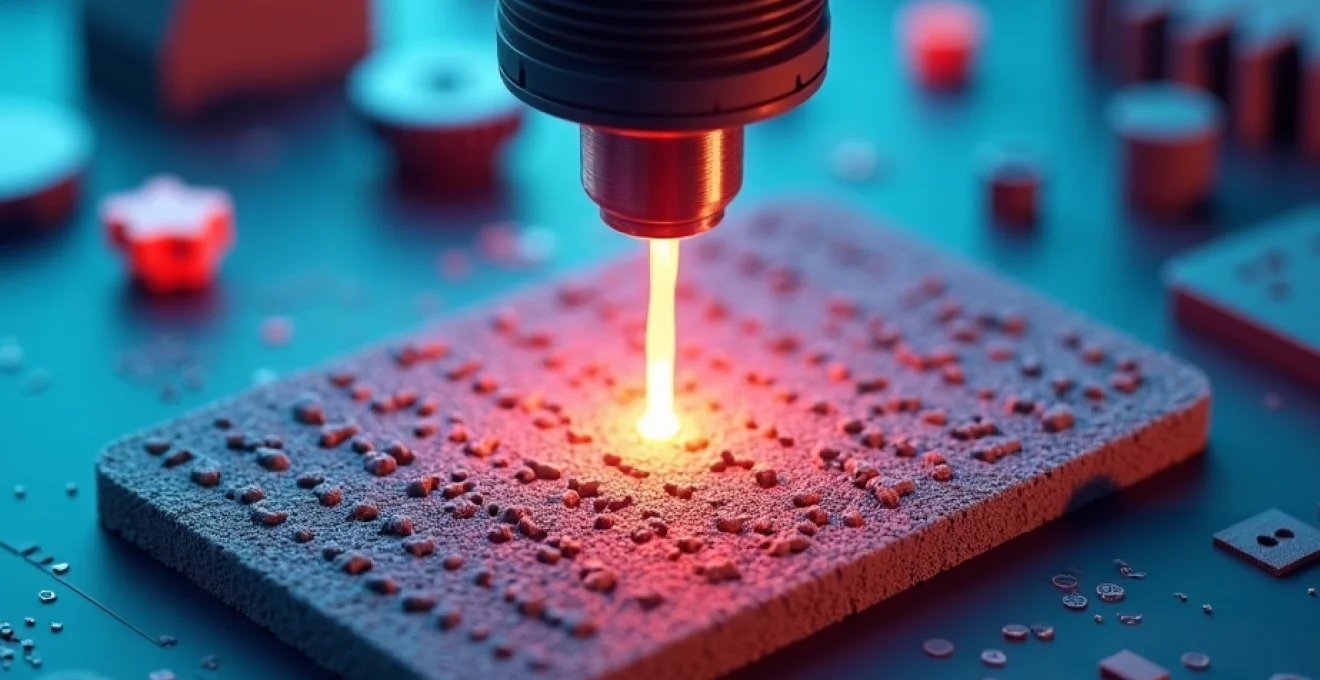

Selective laser sintering (SLS) and direct metal laser sintering (DMLS)

Selective Laser Sintering (SLS) and Direct Metal Laser Sintering (DMLS) are powder-based technologies that use a laser to sinter or melt particles together. SLS is typically used with polymer powders, while DMLS is specifically for metal powders. These techniques offer the advantage of not requiring support structures, as the unfused powder supports the part during building.

SLS and DMLS are capable of producing complex geometries with high accuracy and good mechanical properties. They are particularly valuable in aerospace, automotive, and medical industries for creating functional prototypes and end-use parts. The main challenges include the high cost of equipment and the need for careful powder handling and post-processing.

Binder jetting and material jetting processes

Binder Jetting and Material Jetting are additive manufacturing processes that deposit liquid binders or materials to create objects. In Binder Jetting, a liquid binding agent is selectively deposited onto a powder bed to bond particles together. This technique is versatile and can be used with a variety of materials, including metals, ceramics, and polymers.

Material Jetting, on the other hand, is similar to inkjet printing but in three dimensions. Droplets of build material are deposited layer by layer and cured or solidified. This process allows for multi-material printing and can achieve high resolution and smooth surfaces. Material Jetting is often used for creating realistic prototypes, especially when multiple colours or materials are required.

Advanced AM technologies and applications

As additive manufacturing continues to evolve, new technologies and applications are constantly emerging. These advanced techniques are pushing the boundaries of what’s possible in manufacturing, enabling the creation of parts with unprecedented properties and functionalities.

Electron beam melting (EBM) for aerospace components

Electron Beam Melting (EBM) is an advanced additive manufacturing process particularly well-suited for aerospace applications. EBM uses a high-power electron beam to melt metal powder in a vacuum chamber, allowing for the production of dense, high-purity metal parts. This technology is especially valuable for creating titanium components used in aircraft engines and structural elements.

The vacuum environment of EBM results in parts with excellent material properties, including high strength and low residual stresses. This makes it ideal for producing critical aerospace components that must withstand extreme conditions. Additionally, the ability to create complex internal structures enables the design of lightweight parts that maintain or even improve upon the performance of traditionally manufactured components.

Bioprinting: organ and tissue fabrication techniques

Bioprinting represents one of the most exciting frontiers in additive manufacturing, with the potential to revolutionise healthcare and regenerative medicine. This technology involves the layer-by-layer deposition of bioinks – materials containing living cells – to create tissue-like structures. The ultimate goal of bioprinting is to produce functional organs for transplantation, addressing the critical shortage of donor organs worldwide.

Current bioprinting research focuses on creating tissue models for drug testing, developing personalised implants, and fabricating small-scale organ structures. Challenges include maintaining cell viability during the printing process, achieving the necessary complexity of tissue structures, and ensuring proper vascularisation of printed constructs. Despite these hurdles, bioprinting holds immense promise for personalised medicine and tissue engineering applications.

4D printing: Shape-Memory materials and Self-Assembly

4D printing represents the next evolution in additive manufacturing, incorporating materials that can change shape or properties over time in response to external stimuli. This emerging technology combines 3D printing with smart materials that can transform after production, adding a fourth dimension – time – to the manufacturing process.

Applications of 4D printing include self-assembling furniture, adaptive medical implants, and responsive architectural elements. For example, a 4D-printed stent could be inserted into a blood vessel in a compressed form and then expand to the desired shape when exposed to body temperature. The development of 4D printing technologies opens up new possibilities for creating adaptive and responsive structures across various industries.

Software and design considerations for AM

Successful implementation of additive manufacturing requires sophisticated software tools and a reimagining of traditional design approaches. Computer-aided design (CAD) software optimised for additive manufacturing allows designers to create complex geometries that take full advantage of the technology’s capabilities. These tools often incorporate features such as topology optimisation, which can generate structures that maximise strength while minimising material use.

Designers must also consider the unique constraints and opportunities presented by additive manufacturing processes. This includes accounting for build orientation, support structures, and potential post-processing requirements. Design for Additive Manufacturing (DfAM) principles guide the creation of parts that are not only functional but also optimised for the specific AM process being used.

Simulation software plays a crucial role in predicting how a part will behave during the printing process and in its final application. These tools can help identify potential issues such as thermal distortion or residual stresses before physical production begins, saving time and resources in the development process.

Quality control and Post-Processing in additive manufacturing

Ensuring consistent quality in additive manufacturing requires rigorous control measures throughout the production process. In-situ monitoring systems can track parameters such as melt pool dynamics and layer uniformity in real-time, allowing for immediate adjustments to maintain part quality. Post-build inspection techniques, including CT scanning and 3D metrology, are used to verify the internal structure and dimensional accuracy of printed parts.

Post-processing is often necessary to achieve the desired surface finish, mechanical properties, or aesthetic qualities of additively manufactured parts. Common post-processing techniques include:

- Heat treatment to relieve internal stresses and improve material properties

- Surface finishing methods such as sanding, polishing, or chemical treatment

- Machining to achieve tighter tolerances on critical features

The development of automated post-processing systems is an active area of research, aimed at reducing the labour intensity and improving the consistency of these operations. As additive manufacturing continues to mature, integrating quality control and post-processing considerations into the initial design and production planning stages becomes increasingly important for ensuring the reliability and performance of additively manufactured parts.