Automation in manufacturing has revolutionized the way products are made, significantly boosting efficiency and productivity across industries. As factories embrace cutting-edge technologies, they’re able to streamline processes, reduce errors, and optimize output like never before. This transformation is not just about replacing human workers with machines; it’s about creating smarter, more responsive production systems that can adapt to changing demands and market conditions.

The impact of automation on manufacturing efficiency is profound, touching every aspect of the production process. From robotic assembly lines to AI-powered quality control systems, automation technologies are reshaping the factory floor and redefining what’s possible in terms of speed, precision, and scalability. As you explore the world of automated manufacturing, you’ll discover how these innovations are driving competitiveness and fueling economic growth in the global marketplace.

Principles of automation in manufacturing processes

At its core, automation in manufacturing is guided by several key principles that work together to enhance efficiency. These principles include process standardization, continuous flow, real-time monitoring, and adaptive control. By implementing these concepts, manufacturers can create production systems that are not only faster but also more reliable and flexible.

Process standardization ensures that each task is performed consistently, regardless of who or what is doing the work. This uniformity is crucial for maintaining quality and reducing variability in output. Continuous flow principles minimize bottlenecks and idle time, keeping materials and products moving smoothly through the production line. Real-time monitoring allows for immediate detection of issues, while adaptive control systems can make instant adjustments to optimize performance.

One of the most significant advantages of automation is its ability to operate around the clock without fatigue. This constant productivity can dramatically increase output volumes and reduce per-unit costs. Moreover, automated systems can often perform tasks with a level of precision that surpasses human capabilities, leading to higher quality products and fewer defects.

The integration of these principles results in a manufacturing ecosystem that is more efficient, cost-effective, and capable of meeting the demanding standards of modern consumers. As you delve deeper into the world of automation, you’ll see how these foundational concepts are applied across various technologies and systems.

Industrial robotics and computer numerical control (CNC) systems

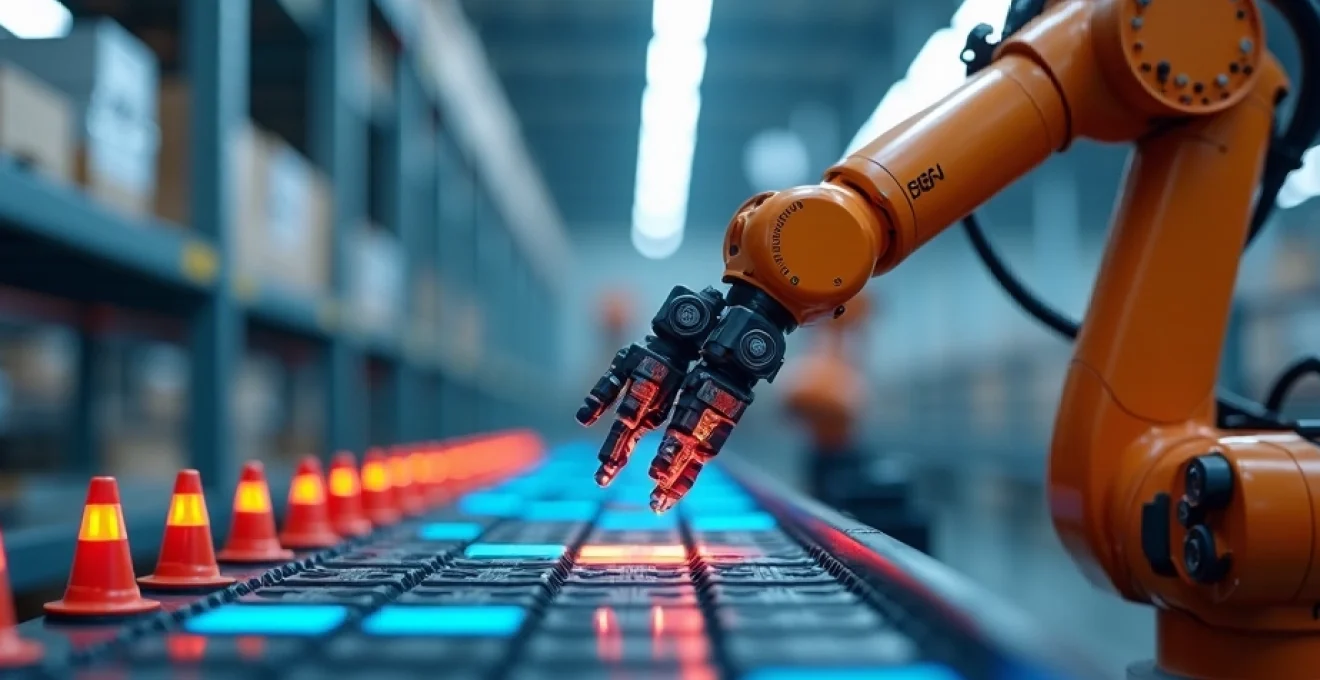

Industrial robotics and CNC systems are at the forefront of manufacturing automation, revolutionizing production lines with their speed, precision, and versatility. These technologies have become indispensable in many industries, from automotive manufacturing to electronics assembly. Let’s explore some of the key components of this robotic revolution:

Articulated robotic arms in assembly lines

Articulated robotic arms are the workhorses of many automated assembly lines. These versatile machines can perform a wide range of tasks, from welding and painting to pick-and-place operations. With multiple joints that mimic human arm movements, these robots can reach into tight spaces and handle complex assembly tasks with ease.

The efficiency gains from using articulated robotic arms are substantial. They can work continuously without breaks, maintain consistent quality, and perform repetitive tasks without fatigue. This leads to increased production rates and reduced labor costs. Additionally, these robots can be reprogrammed quickly to adapt to new product designs or manufacturing processes, providing flexibility that is crucial in today’s fast-paced market.

SCARA robots for Pick-and-Place operations

SCARA (Selective Compliance Assembly Robot Arm) robots are specifically designed for high-speed pick-and-place operations. These robots excel in tasks that require rapid, precise movements in a horizontal plane, such as assembling small electronic components or packaging products.

The efficiency of SCARA robots lies in their simplicity and speed. With fewer moving parts than articulated arms, they can achieve incredibly fast cycle times, sometimes completing multiple operations per second. This speed translates directly into higher throughput and improved productivity on the factory floor.

CNC machining centers for precision parts production

Computer Numerical Control (CNC) machining centers represent the pinnacle of precision in automated manufacturing. These sophisticated machines can produce complex parts with incredibly tight tolerances, often working with accuracies measured in microns. CNC systems interpret computer-aided design (CAD) files and translate them into precise cutting paths, ensuring consistency across large production runs.

The efficiency improvements offered by CNC machining are multifaceted. Not only can these machines work around the clock with minimal human intervention, but they also reduce material waste through optimized cutting paths. Furthermore, the ability to quickly switch between different part designs without retooling means manufacturers can respond rapidly to changing customer demands or produce small batches of customized products efficiently.

Collaborative robots (cobots) in Human-Machine interaction

Collaborative robots, or cobots, represent a new frontier in manufacturing automation. Unlike traditional industrial robots that are caged off for safety reasons, cobots are designed to work alongside human operators. This collaboration between humans and robots combines the strength and precision of machines with the problem-solving skills and flexibility of human workers.

The efficiency gains from cobots come from their ability to enhance human capabilities rather than replace them entirely. For example, a cobot might handle the heavy lifting in an assembly task while a human worker performs more delicate operations or quality checks. This division of labor plays to the strengths of both human and machine, resulting in improved overall productivity and reduced physical strain on workers.

Advanced sensors and machine vision technology

Advanced sensors and machine vision systems are the eyes and ears of automated manufacturing processes. These technologies enable machines to perceive their environment, make decisions, and ensure quality control with a level of accuracy and consistency that surpasses human capabilities. Let’s examine some key applications of these technologies:

3D vision systems for quality inspection

Three-dimensional vision systems have transformed quality inspection processes in manufacturing. These systems use lasers, structured light, or multiple cameras to create detailed 3D models of products as they move along the production line. This technology allows for comprehensive inspection of complex geometries, surface finishes, and dimensional accuracy.

The efficiency gains from 3D vision systems are significant. They can perform 100% inspection at production speeds, catching defects that might be missed by human inspectors or traditional 2D vision systems. This leads to improved product quality, reduced scrap rates, and fewer customer returns. Moreover, the data collected by these systems can be used to identify trends and optimize production processes over time.

LIDAR and proximity sensors for safety and navigation

LIDAR (Light Detection and Ranging) and proximity sensors play a crucial role in ensuring safety and efficient navigation in automated manufacturing environments. LIDAR systems use laser pulses to create detailed maps of the surrounding area, allowing robots and automated guided vehicles (AGVs) to navigate complex factory layouts with precision.

The efficiency improvements from these sensors are twofold. First, they enable safe operation of mobile robots and AGVs in shared spaces with human workers, reducing the need for segregated work areas. Second, they optimize pathfinding and traffic management in the factory, ensuring smooth material flow and minimizing idle time. This results in a more fluid and productive manufacturing environment.

Optical character recognition (OCR) in product tracking

Optical Character Recognition (OCR) technology has revolutionized product tracking and traceability in manufacturing. OCR systems can read text and codes on products or packaging at high speeds, enabling real-time tracking of items throughout the production process and supply chain.

The efficiency gains from OCR are substantial. It eliminates the need for manual data entry, reducing errors and labor costs. OCR also enables automated sorting and routing of products based on their identifiers, streamlining logistics operations. Furthermore, the ability to quickly capture and process product information facilitates better inventory management and quality control processes.

Infrared thermography for predictive maintenance

Infrared thermography is a powerful tool for predictive maintenance in manufacturing. By detecting heat signatures of machinery and electrical systems, infrared cameras can identify potential issues before they lead to breakdowns or failures. This non-contact method of inspection allows for continuous monitoring without disrupting production.

The efficiency improvements from infrared thermography are primarily in the realm of maintenance and downtime reduction. By catching problems early, manufacturers can schedule maintenance during planned downtime, avoiding unexpected failures that can halt production. This proactive approach to maintenance can significantly improve overall equipment effectiveness (OEE) and reduce maintenance costs over time.

Artificial intelligence and machine learning in manufacturing

Artificial Intelligence (AI) and Machine Learning (ML) are transforming manufacturing by introducing unprecedented levels of intelligence and adaptability to automated systems. These technologies enable machines to learn from data, make decisions, and continuously improve their performance. Let’s explore some key applications:

Predictive analytics for equipment maintenance

Predictive analytics powered by AI and ML is revolutionizing equipment maintenance strategies. By analyzing vast amounts of sensor data from machines, these systems can predict when equipment is likely to fail or require maintenance. This shift from reactive to predictive maintenance can dramatically reduce downtime and extend the lifespan of expensive machinery.

The efficiency gains from predictive maintenance are substantial. By scheduling maintenance only when it’s needed, manufacturers can avoid unnecessary downtime and reduce maintenance costs. Moreover, by preventing unexpected breakdowns, predictive maintenance ensures more consistent production schedules and higher overall equipment effectiveness.

Deep learning algorithms for defect detection

Deep learning algorithms have taken quality control to new heights in manufacturing. These sophisticated AI systems can be trained on large datasets of product images to identify even subtle defects that might be missed by traditional machine vision systems or human inspectors.

The efficiency improvements from deep learning-based defect detection are multifaceted. These systems can operate at production speeds, enabling 100% inspection without slowing down the line. They can also adapt to new types of defects over time, improving their accuracy and reducing false positives. This leads to higher product quality, reduced scrap rates, and increased customer satisfaction.

Neural networks in process optimization

Neural networks are being applied to process optimization in manufacturing, creating systems that can continuously adjust and improve production parameters. These AI models can analyze complex interactions between various factors in a production process and suggest optimal settings for maximum efficiency and quality.

The efficiency gains from neural network-based process optimization can be significant. By fine-tuning production parameters in real-time, manufacturers can reduce energy consumption, minimize material waste, and improve product quality. Over time, these systems can learn from their own performance, leading to continuous improvement in production efficiency.

Natural language processing for Voice-Controlled systems

Natural Language Processing (NLP) is making its way onto the factory floor through voice-controlled systems. These AI-powered interfaces allow workers to interact with machines and access information hands-free, which is particularly useful in environments where manual input might be impractical or unsafe.

The efficiency improvements from NLP-based systems come from enhanced worker productivity and reduced errors. Operators can quickly access manuals, report issues, or control equipment using voice commands, allowing them to focus on their tasks without interruption. This can lead to faster problem resolution, improved safety, and more efficient training processes for new employees.

Internet of things (IoT) and connected factory systems

The Internet of Things (IoT) is transforming manufacturing by creating interconnected networks of sensors, machines, and data systems. This connectivity enables real-time monitoring, analysis, and control of production processes on an unprecedented scale. The result is a “smart factory” where every aspect of production is optimized for maximum efficiency.

IoT in manufacturing goes beyond simply connecting devices; it creates an ecosystem where data flows seamlessly between machines, management systems, and even across different facilities. This level of integration allows for more informed decision-making, faster response to issues, and the ability to optimize operations across entire supply chains.

One of the key efficiency gains from IoT in manufacturing is the ability to implement dynamic production scheduling. By analyzing real-time data from machines, inventory systems, and demand forecasts, IoT-enabled systems can adjust production schedules on the fly to maximize throughput and minimize waste. This agility is crucial in today’s fast-paced markets where demand can shift rapidly.

Another significant benefit of connected factory systems is improved energy management. IoT sensors can monitor energy consumption across the factory in real-time, identifying inefficiencies and automatically adjusting systems to reduce waste. This not only lowers operating costs but also contributes to sustainability goals, which are increasingly important in modern manufacturing.

Automated material handling and warehousing solutions

Automated material handling and warehousing solutions are revolutionizing the way manufacturers manage inventory and move goods through their facilities. These systems range from simple conveyor belts to complex robotic storage and retrieval systems. Let’s explore some key technologies in this area:

Automated guided vehicles (AGVs) for intralogistics

Automated Guided Vehicles (AGVs) are transforming intralogistics in manufacturing facilities. These self-driving vehicles can transport materials, components, and finished products throughout the factory without human intervention. AGVs use a combination of sensors, cameras, and mapping technology to navigate safely and efficiently.

The efficiency gains from AGVs are substantial. They can operate 24/7, reducing labor costs and increasing throughput. AGVs also improve safety by reducing the risk of accidents associated with manual material handling. Furthermore, their routes can be easily reprogrammed to adapt to changes in factory layout or production requirements, providing flexibility that is crucial in modern manufacturing environments.

Automated storage and retrieval systems (AS/RS)

Automated Storage and Retrieval Systems (AS/RS) are high-density storage solutions that use robotic systems to store and retrieve items. These systems can maximize vertical space utilization, making them ideal for facilities with limited floor space. AS/RS can handle a wide range of items, from small components to large pallets.

The efficiency improvements from AS/RS are multifaceted. They dramatically reduce the time required to locate and retrieve items, improving order fulfillment speeds. The high-density storage also reduces the overall footprint required for warehousing, potentially leading to significant cost savings. Additionally, these systems provide real-time inventory tracking, reducing errors and improving inventory management.

Robotic palletizers and depalletizers

Robotic palletizers and depalletizers automate the process of stacking products onto pallets or removing them for further processing or shipping. These systems can handle a variety of product sizes and shapes, adapting their stacking patterns to maximize stability and space utilization.

The efficiency gains from robotic palletizing systems are significant. They can work at high speeds without fatigue, increasing throughput and consistency. These systems also reduce the risk of injury associated with manual palletizing, which can be a physically demanding task. Furthermore, robotic palletizers can optimize pallet loads for better space utilization in warehouses and during transport.

Conveyor systems and sortation technology

Advanced conveyor systems and sortation technologies form the backbone of many automated material handling solutions. Modern conveyor systems can transport products quickly and efficiently throughout a facility, while intelligent sortation systems can route items to their correct destinations based on barcodes, RFID tags, or other identifiers.

The efficiency improvements from these systems are substantial. They can move large volumes of products with minimal human intervention, reducing labor costs and improving accuracy. Sortation systems can also significantly speed up order fulfillment processes, enabling faster shipping times and improved customer satisfaction. Additionally, these systems can be integrated with warehouse management software to provide real-time tracking and inventory management capabilities.